Birdhouses made from Post-consumer recycled number 2 plastics–High Density Polyethylene (HDPE)–are a safe and durable option.

HDPE birdhouses are a great option for bird lovers who want to provide a safe and durable home for their feathered friends. Here are some of the reasons why HDPE is a good material for birdhouses:

- HDPE will not be damaged by UV rays, and is a very durable material that can withstand the elements, including rain, snow, and wind. This means that the birdhouse will last for years to come, and provide a safe and comfortable home for birds. HDPE is a non-hazardous material and its over exposure by short term or long term inhalation does not cause any harmful health effects.

- HDPE is, like BPA, a material derived from petroleum. The difference is that HDPE plastics are completely free from BPA and are therefore safe for applications that directly impact humans.

- HDPE is a non-toxic material, which means that it is safe for birds and other wildlife.

- HDPE is also easy to clean, which is important for birdhouses that are used for nesting. Birds can bring in dirt, debris, and parasites into their nests, so it is important to be able to clean the birdhouse regularly to prevent the spread of disease.

First Step: collecting, cleaning, and sorting

This project requires significant amounts of post-consumer recycled HDPE plastic, so we need a lot of No. 2 plastic. Since May, we have been collecting, cleaning, removing labels, and sorting the post-consumer recycled HDPE plastic. The first step to building a birdhouse out of plastic is to collect, clean, and sort through all the plastic. Cleaning the post-consumer plastic is the most time-consuming step of the plastic birdhouse making process, as many of the labels leave a sticky residue that is very difficult to remove.

Cutting + Shredding + Sorting post-consumer HDPE

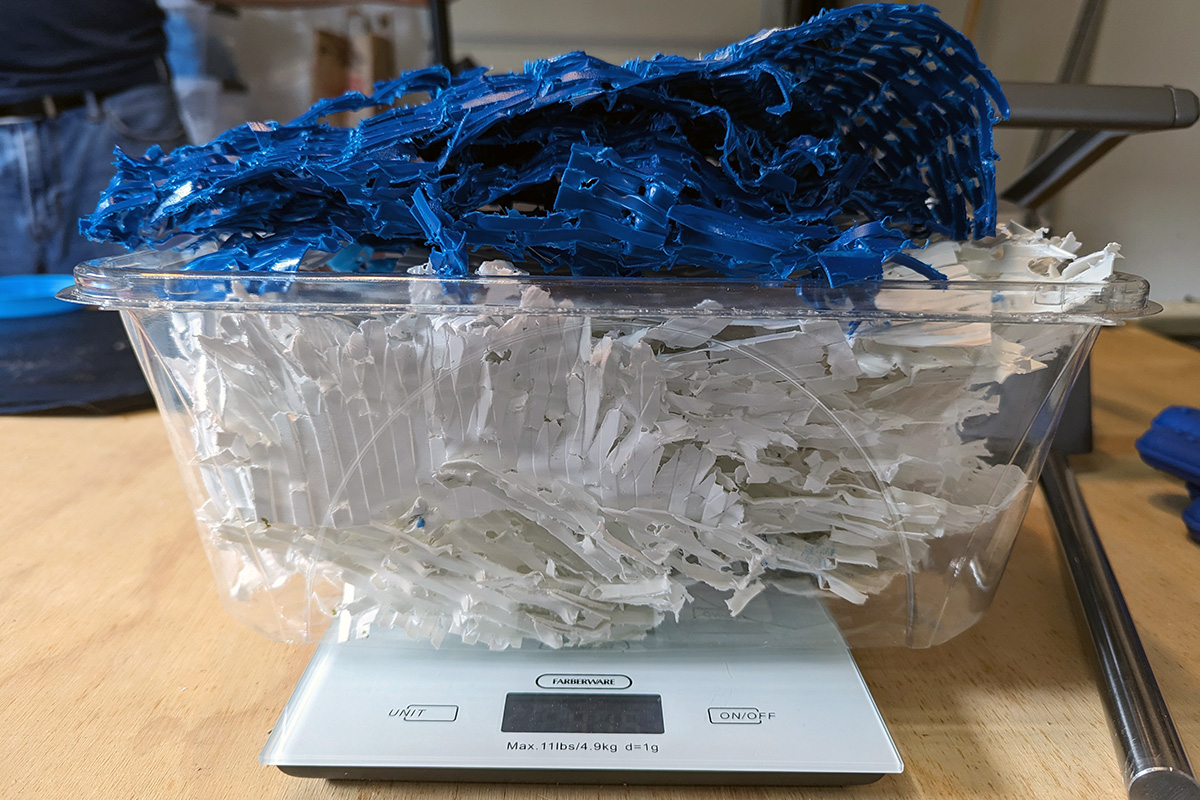

We then used various knives to cut the plastic bottles down to a size where it could be run through the shredder. Cutting the plastic down and shredding it is important so that it will melt faster, making the construction process easier.

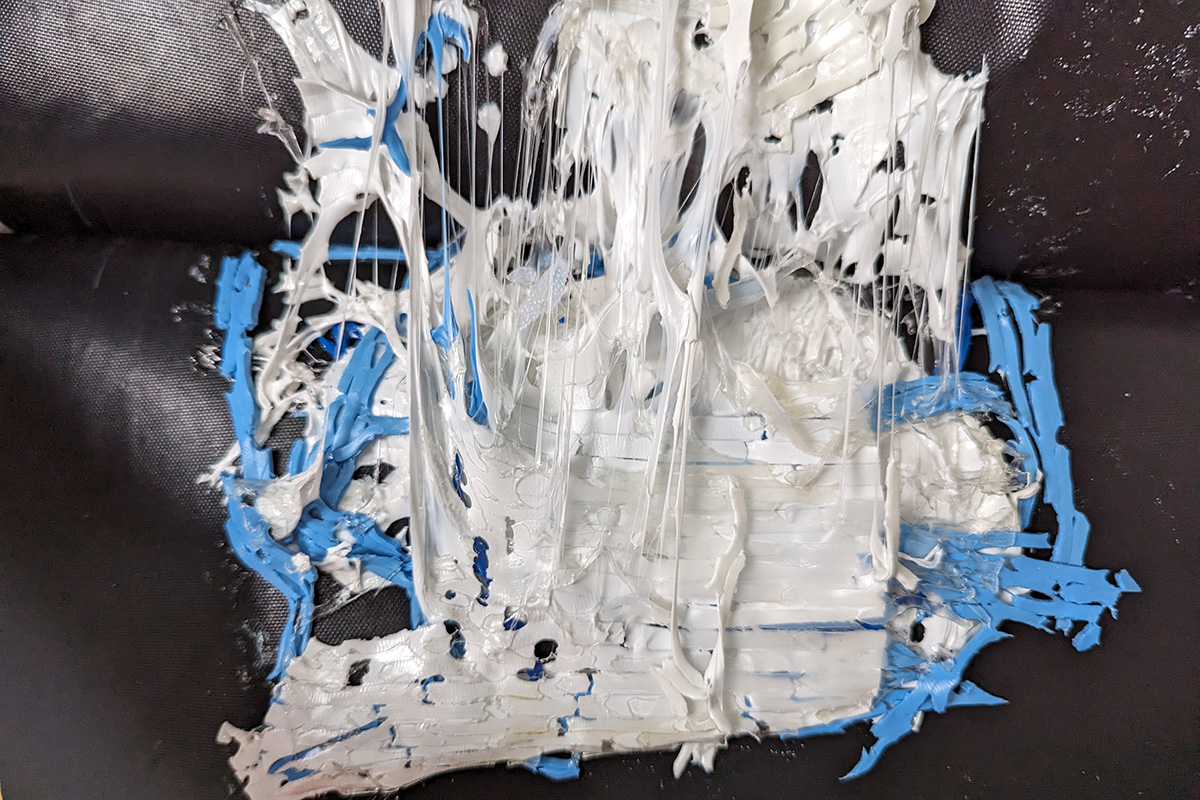

HDPE does not bond well to other materials, which is why we are using colored HDPE mixed with white and translucent HDPE to add color to our birdhouse.

Weighing:

HDPE density = 0.93-0.97 g/cm3 (used 0.94 g/cm3)

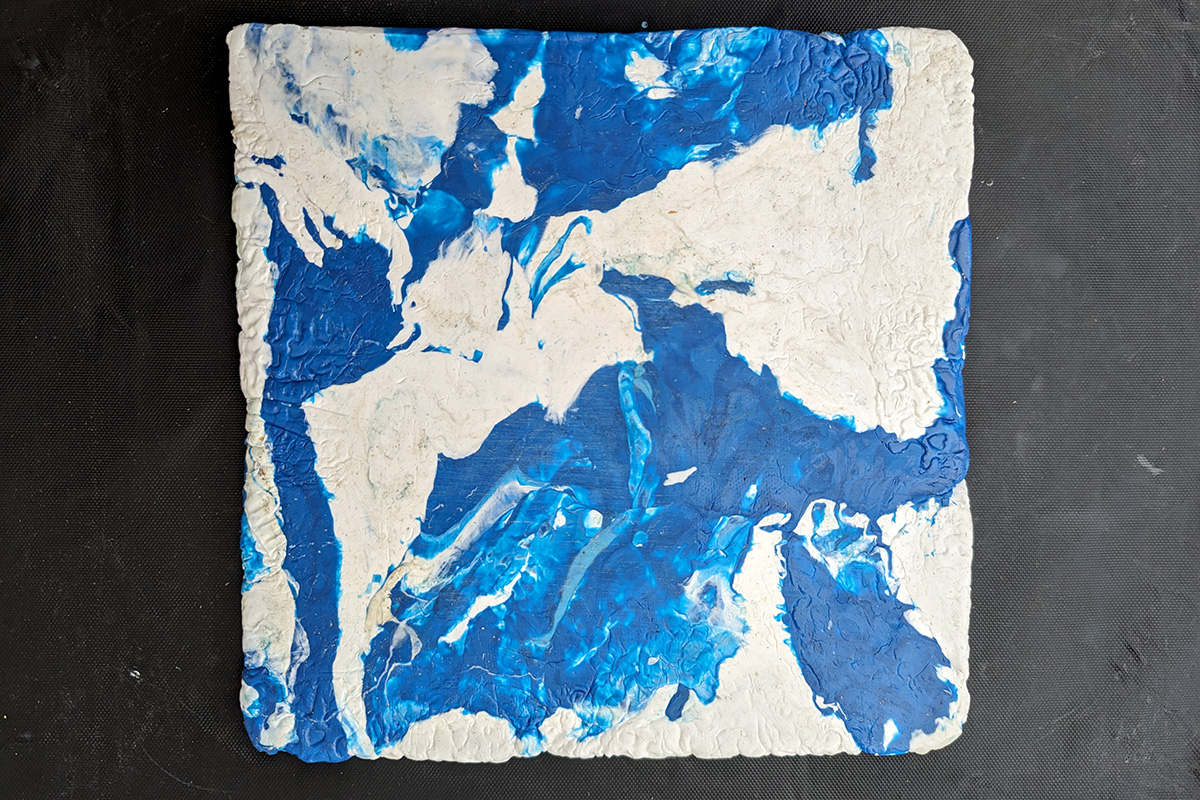

In order to make around an eight by eight piece of HDPE plastic, it takes around 417 grams. This is approximately equivalent to 4 1-gallon milk jugs and 1 detergent bottle.

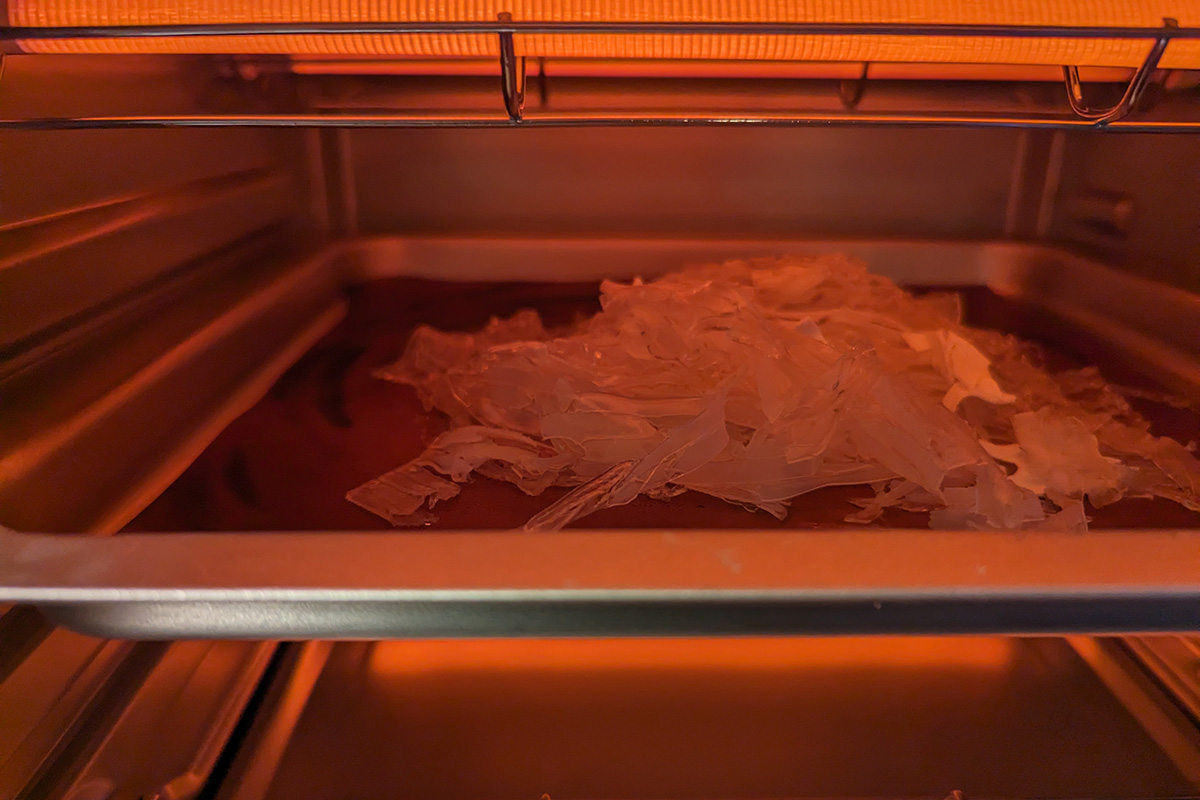

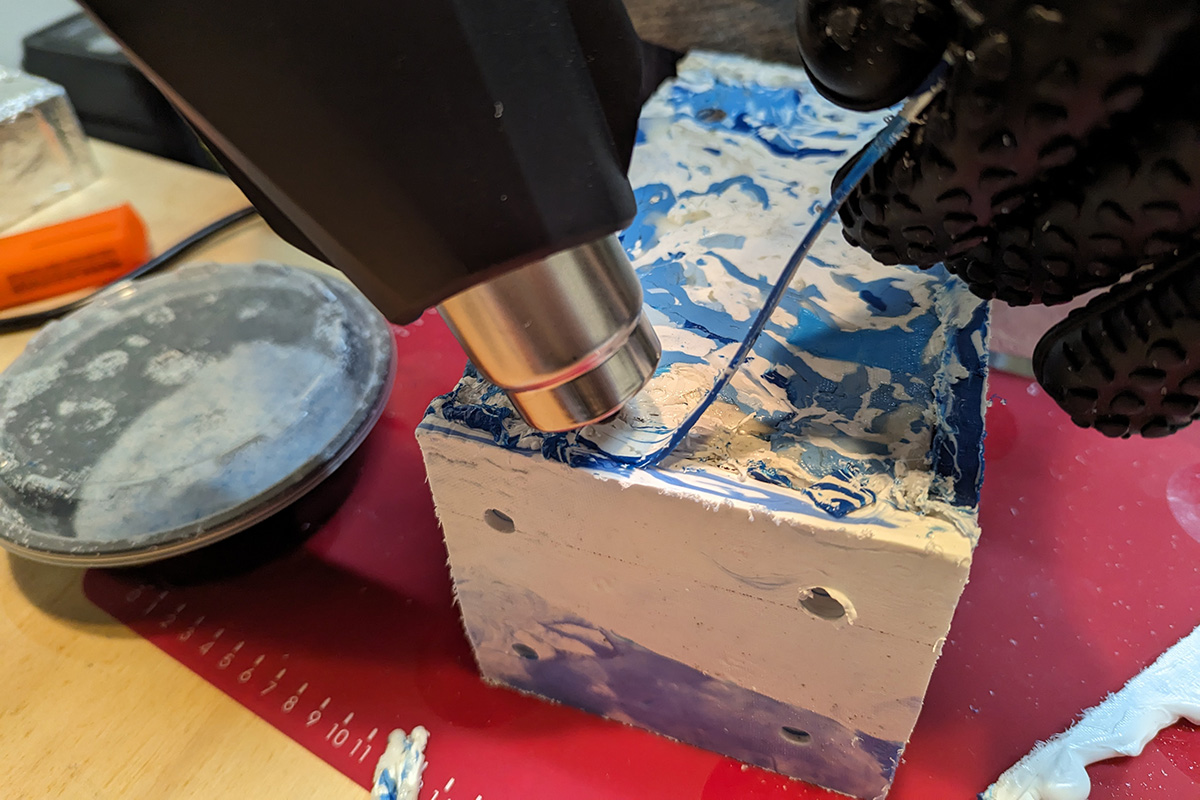

Melt HDPE

To make the birdhouse, we melted down the plastic using both a heat press and oven at 345°F and then pressed it into a mold. Each piece took around 40 minutes to melt, including prep time.

Form and Shape HDPE

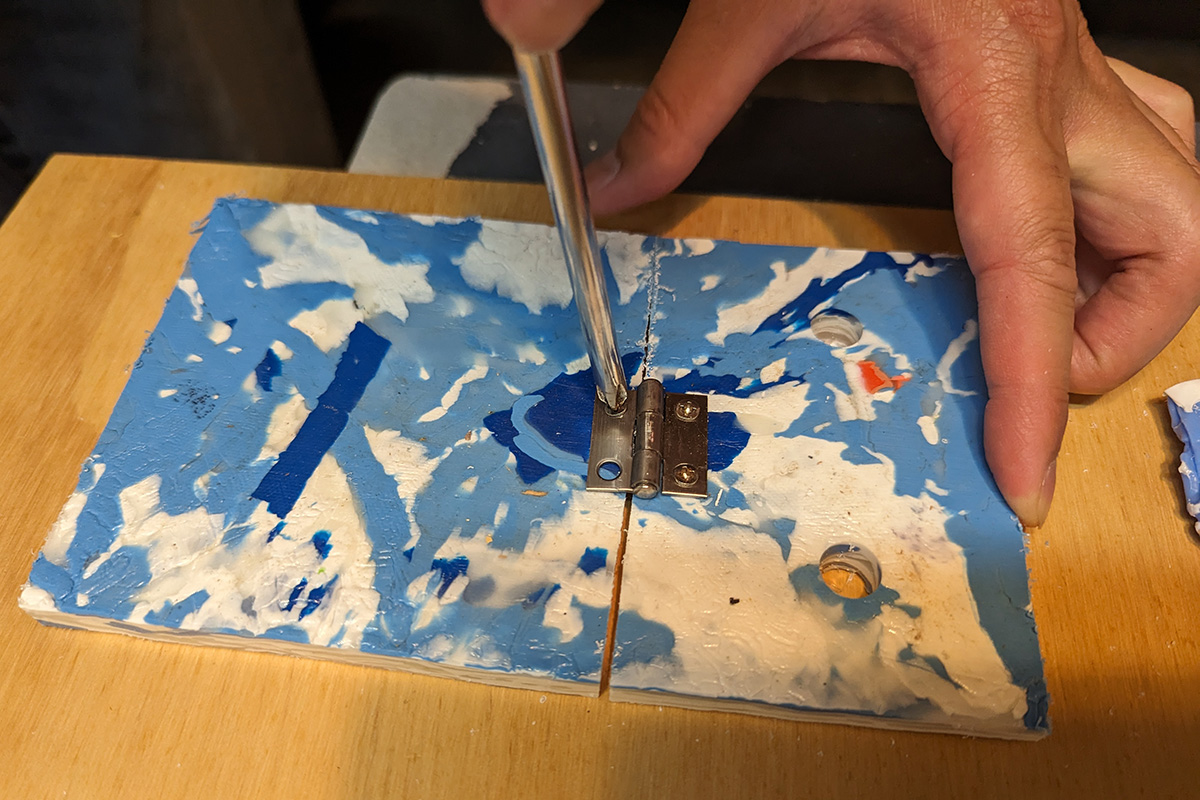

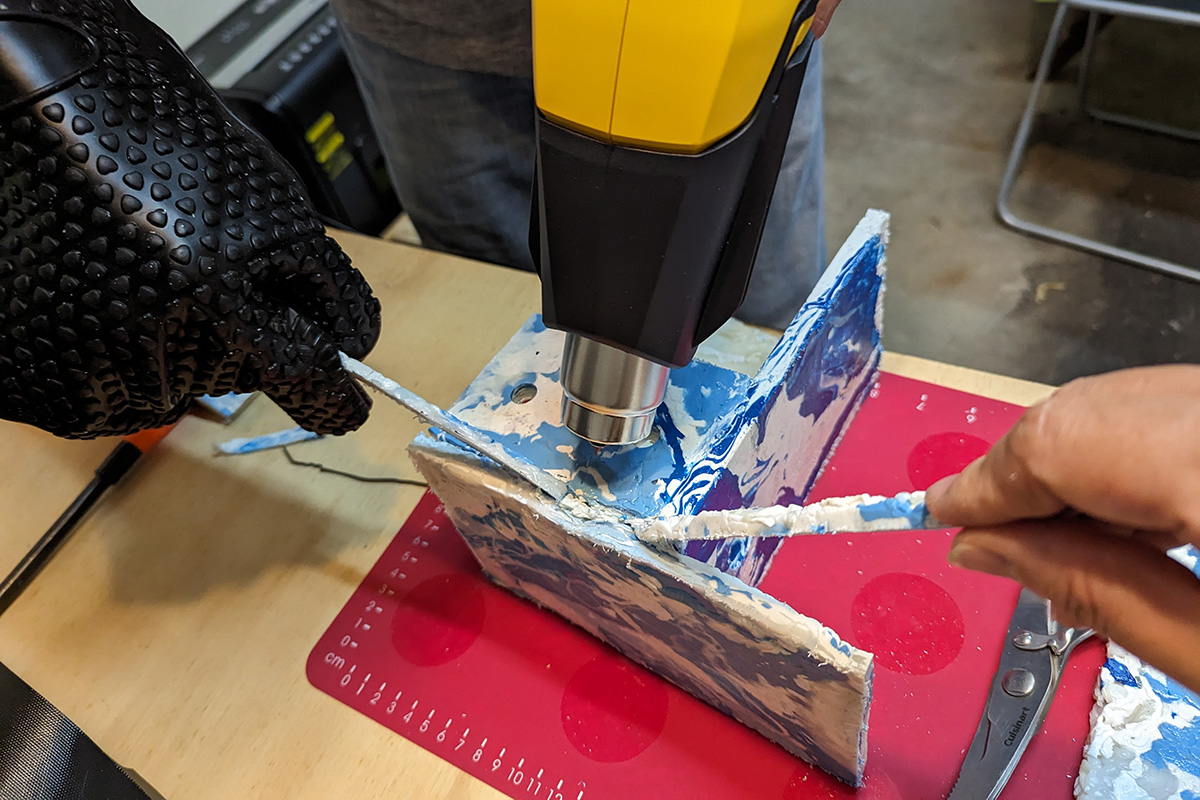

Cut and Weld HDPE

After making all the necessary pieces, they are cut to size and welded together. We chose to plastic weld the birdhouse together as opposed to glue or screws because HDPE does not bind to the glue well and screws may not hold the plastic together well enough.

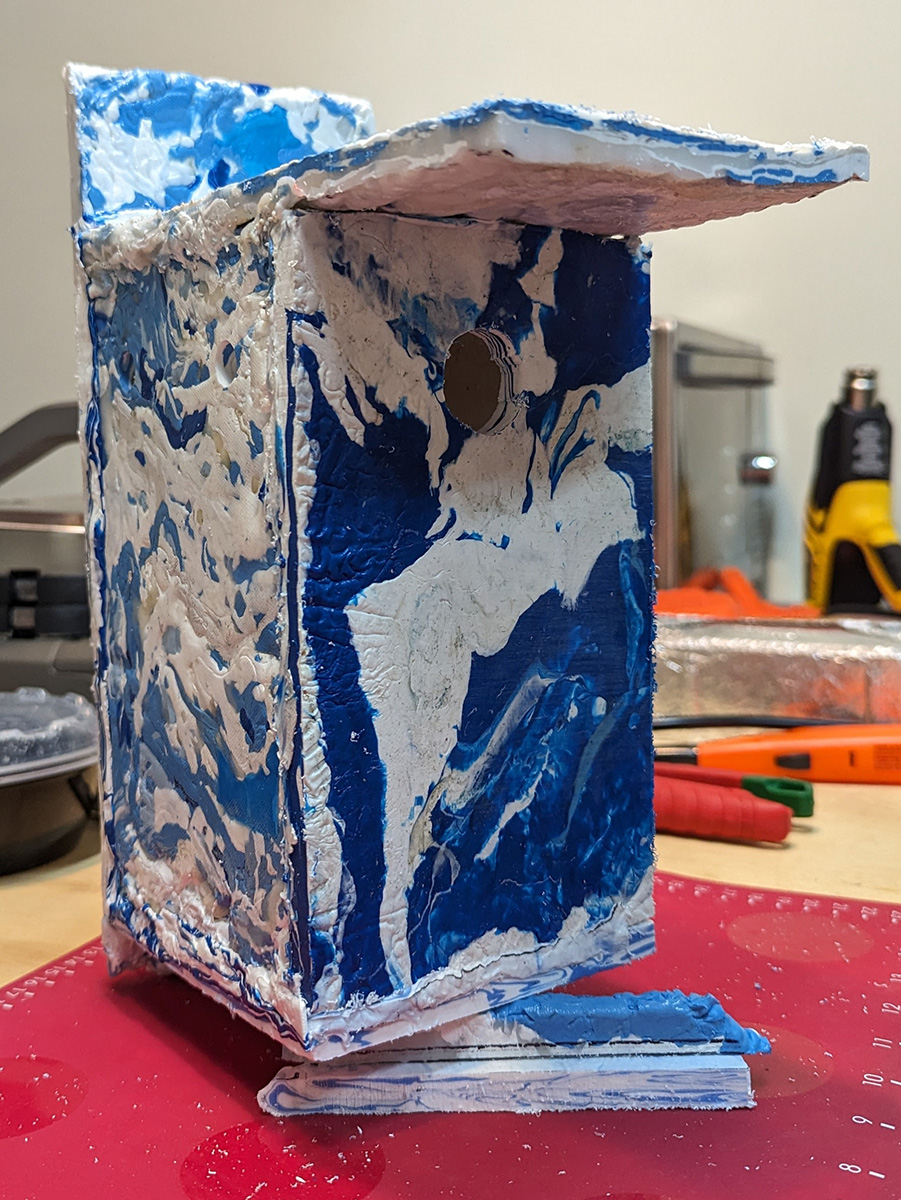

We are proud of our recycled birdhouse and we know that it will provide a safe and comfortable home for birds for years to come. We hope that our project will inspire others to reuse and recycle materials to create sustainable and cost-effective birdhouses.

[Download] Nest Box Construction Plan

from Cornell Lab of Ornithology–NestWatch

House and Bewick’s Wrens; Black-capped, Mountain, Boreal, Chestnut-backed, and Carolina Chickadees; Juniper, Black-crested, Oak, Tufted, and Bridled Titmice; Pygmy, White-breasted, Red-breasted, and Brown-headed Nuthatches; Prothonotary Warblers; and Flying Squirrels

[Download] Nest Shelf Construction Plan

from Cornell Lab of Ornithology–NestWatch

American Robin, Barn Swallow, Eastern and Say’s Phoebes

Learn About Nest Boxes and Nest Structures

Nest Box and Nest Structure Plans (BY SPECIES)

A nest box made of Post-consumer High Density Polyethylene (HDPE) Plastic

Garage workshop of making HDPE recycled products